Slurry treatment plant , also called slurry treatment system. which is designed and manufactured by Crauntec is widely used for the slurry treatment in the fields of trenchless, HDD,TBM, Pipe Jacking, rotatry drilling, cutter drilling, diaphragm wall and piling project, It can reduce the construction cost and improve the construction efficiency. It is the necessary equipment for the foundation construction.

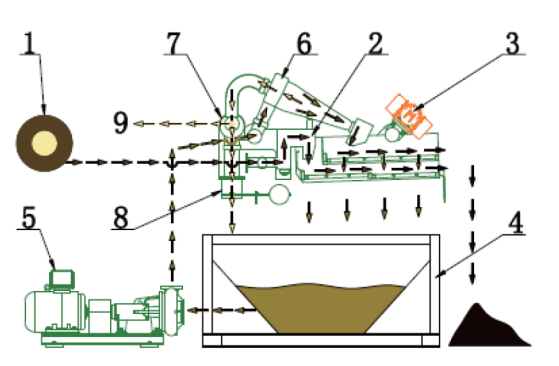

←Crauntec Slurry Treatment Plant Functional Schematic

←Crauntec Slurry Treatment Plant Functional Schematic

1. The slurry suctioned by the slurry pump from the working machinery (or sedimentation tank) (1) enter to the bottom coarse screen of the shale shaker (3) across the shale shaker logging tank (2), the coarse particles will be separated from the slurry here.

2. The liquid phase discharged from step1 go to the slurry tank(4), the slurry supply pump(5) sucks from the tank, injects the slurry with certain kinetic energy from the slurry inlet of the desander(6) along the pipeline, and the fine sand is discharged from the drip nozzle at the lower end of the cyclone and falls onto the upper fine screen of the vibrating shale shaker(3).

3. The dry fine slag material is separated after dewatering and screening by fine screen, and the slurry passing through the fine screen is returned to the slurry storage tank (4) again.

4. The clean mud treated by hydrocyclone (6) enters into the middle storage (7) tank from the overflow pipe of hydrocyclone, and then piped out or returned to the slurry storage tank (4) along the slurry outlet pipe.

5. A liquid level buoy (8) between the middle storage tank and the slurry storage tank keeps the liquid level in the slurry tank constant during mud circulation, once the output of slurry in the storage tank is greater than the supply, the level buoy will fall with the decrease of the liquid level. At this time, the slurry in the middle tank will be piped to the slurry storage tank through the open slurry feeding pipe, and the liquid level will rise and return to its original state; if the slurry supply is greater than the output, the slurry tank will overflow to prevent slurry overflowing. When higher quality mud is required, the purpose can be achieved by reducing the total slurry feed and repeating the mud separation process in the cyclone.

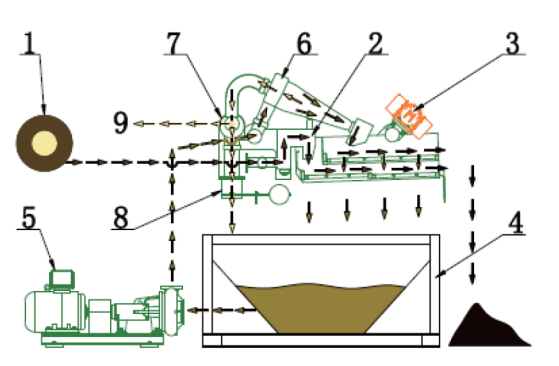

←Crauntec Slurry Treatment Plant Functional Schematic

←Crauntec Slurry Treatment Plant Functional Schematic1. The slurry suctioned by the slurry pump from the working machinery (or sedimentation tank) (1) enter to the bottom coarse screen of the shale shaker (3) across the shale shaker logging tank (2), the coarse particles will be separated from the slurry here.

2. The liquid phase discharged from step1 go to the slurry tank(4), the slurry supply pump(5) sucks from the tank, injects the slurry with certain kinetic energy from the slurry inlet of the desander(6) along the pipeline, and the fine sand is discharged from the drip nozzle at the lower end of the cyclone and falls onto the upper fine screen of the vibrating shale shaker(3).

3. The dry fine slag material is separated after dewatering and screening by fine screen, and the slurry passing through the fine screen is returned to the slurry storage tank (4) again.

4. The clean mud treated by hydrocyclone (6) enters into the middle storage (7) tank from the overflow pipe of hydrocyclone, and then piped out or returned to the slurry storage tank (4) along the slurry outlet pipe.

5. A liquid level buoy (8) between the middle storage tank and the slurry storage tank keeps the liquid level in the slurry tank constant during mud circulation, once the output of slurry in the storage tank is greater than the supply, the level buoy will fall with the decrease of the liquid level. At this time, the slurry in the middle tank will be piped to the slurry storage tank through the open slurry feeding pipe, and the liquid level will rise and return to its original state; if the slurry supply is greater than the output, the slurry tank will overflow to prevent slurry overflowing. When higher quality mud is required, the purpose can be achieved by reducing the total slurry feed and repeating the mud separation process in the cyclone.

Craun can provide the customized service according to the customers’ specific demand, any demand or more detailed information, contact us at grace@crauntec.com.