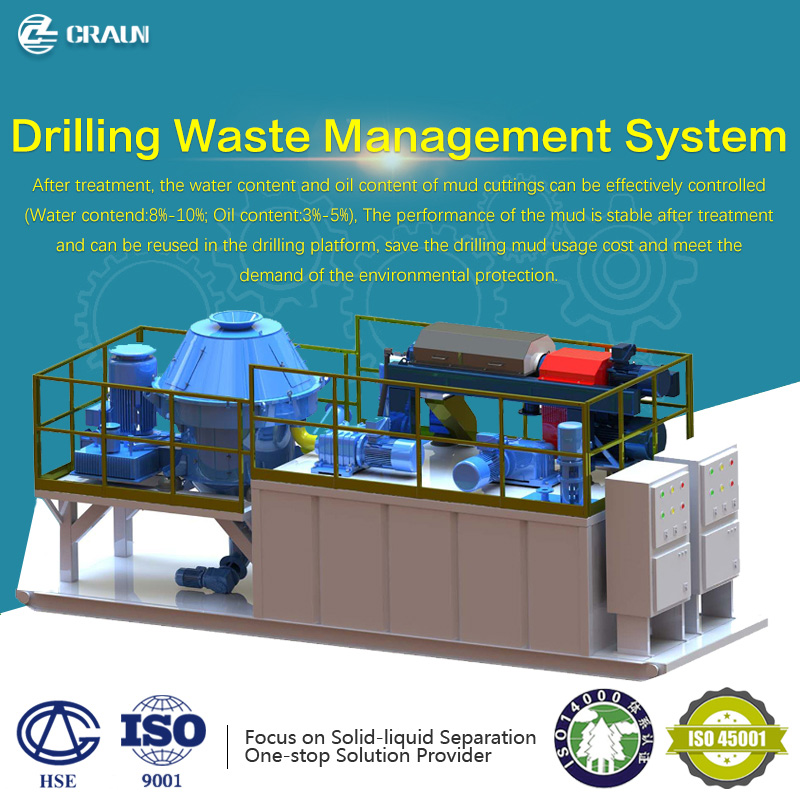

Drilling waste management are probably the biggest challenge facing the industry today in many parts of the world. To meet the environmental compliance, stringent limitations concerning the discharge of Non-Aqueous Fluid (NAF) contaminated drill cuttings to the environment have been addressed by governments. To comply with these requirements, specialized technology has been developed to further treat the drill cuttings after the normal Solids Control Equipment.

Craun provide the full line of drilling waste management equipment for the drilling, with our drilling waste management system, operators are able to run the closed loop mud circulation system to reduce the cost for drilling waste handling.

Three drilling waste management plans can be provided by craun.

Plan1

The system consists of vertical cutting dryer ,high speed VFD decenter centrifuge, conveying system and tanks, used for treatment of oil-based & water based mud. The treatment mud can be reused in drilling platform,

Plan2

The system consists of high G drying shaker, high speed VFD centrifuge, conveying system and tanks, used for treatment of oil -based & waster-based mud.

Plan3

The system consists of H-G drying shaker, diaphragm filter press, dosing device, flocculation tank and storage tanks, it is mainly used for high viscosity water based mud DWM and tail slurry treatment, Advantages are good dehydration effect and low moisture content of solid phase.