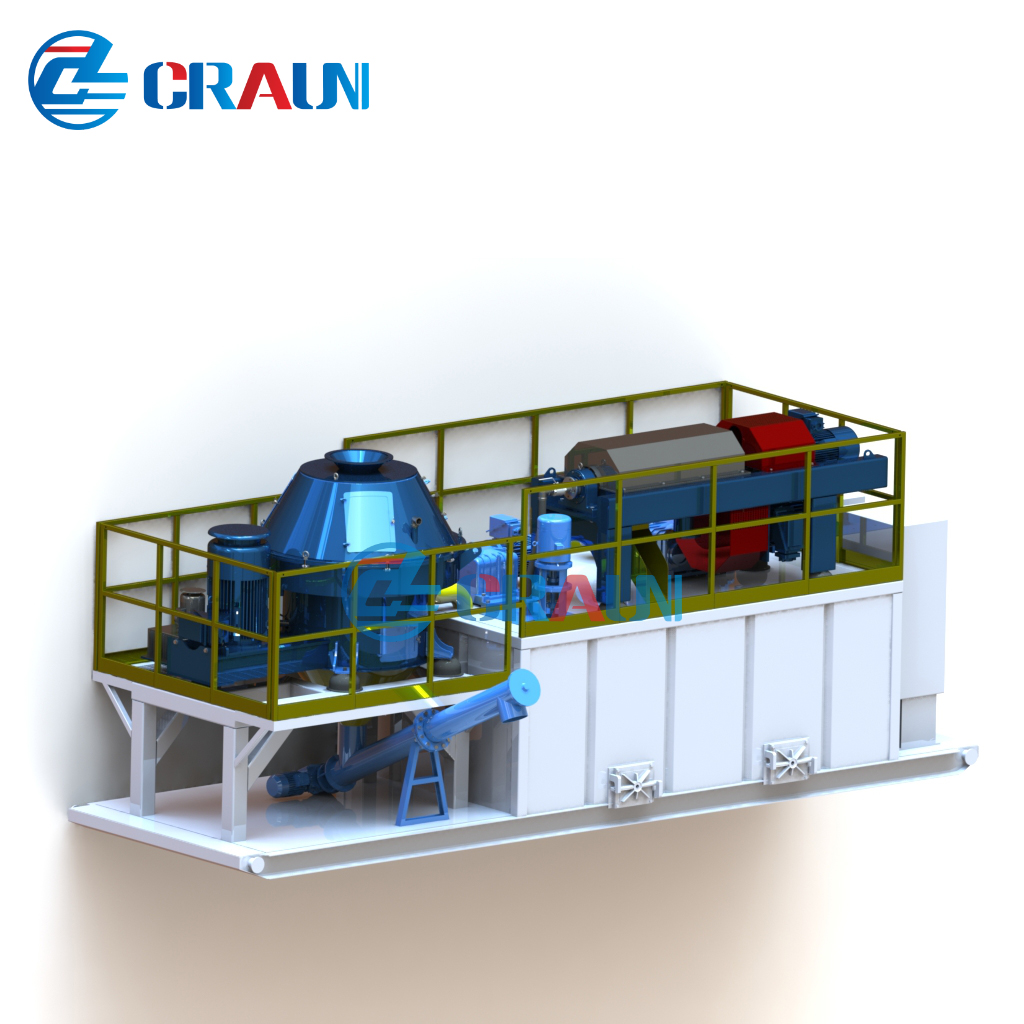

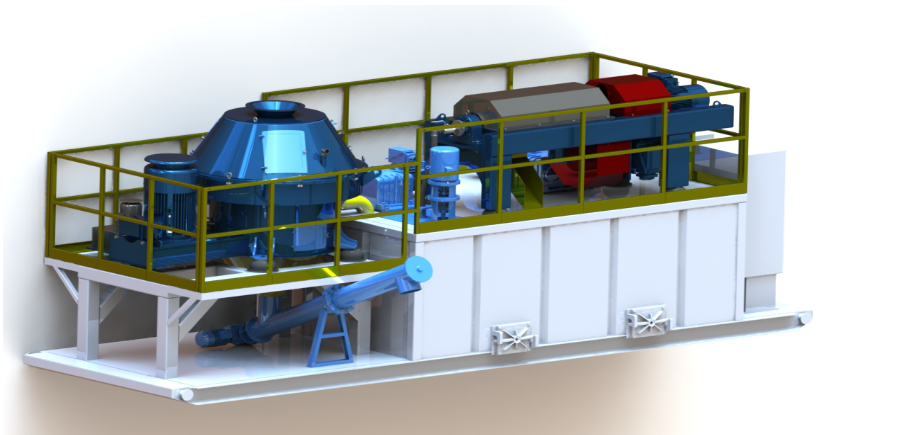

OBM Treatment Equipment

The oil-based waste mud treatment equipment is mainly composed of drilling cuttings dryer, high-speed frequency conversion centrifuge, conveying system and storage tank. The system is equipped with air back blowing system and clean water flushing system to effectively prevent screen blockage. It is mainly used for the treatment of oil-based waste mud. The treatment process does not add any chemicals. The treated mud can be reused for the drilling platform. The connection mode can be designed into two ways: while drilling and off-line centralized treatment to meet the different operation requirements of the drilling crew.

Crauntec, as an professional equipment manufacturer of centrifuge and vertical cutting dryer, has rich design experience and on-site experience, and has added new improvements to the previous equipment to help customers recover more useful mud and greatly reduce the failure rate of the equipment.

Vertical Cutting Dryer:

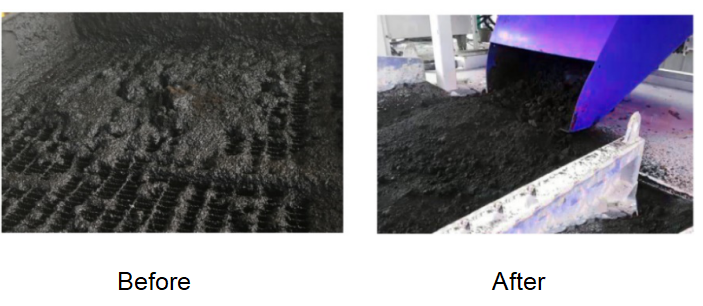

Drilling cuttings dryer is a kind of vertical scraper discharge centrifuge which works continuously. It uses the principle of centrifugal force to separate solid and liquid. It is mainly used in the project of drilling mud not falling to the ground to recover the oil components in the mud, so as to achieve the purpose of reuse, saving and environmental protection. Its OOC is less than 5% after oil-based mud treatment, and its treatment capacity can reach 30-50 tons per hour.

Features:

1.Discharging scraper adopts high chromium cast iron with long service life;

2. The screen is made of SS316L stainless steel with strong corrosion resistance, and the different screen gap size can be selected;

3. Independent circulating oil lubrication and cooling system to ensure continuous operation of equipment;

4. Independent design of air knife back blowing system can effectively prevent screen blocking;

5. FAG brand bearing is used in the dryer, and the speed of 900rpm can reach 420G separation factor, which can effectively separate oil-based mud, composite mud cuttings, and meet the requirements of environmental protection treatment;

6. High precision assembly requirements and strict dynamic balance test ensure the continuity and stability of the equipment in the field operation.

Technical Parameter:

|

Model |

GLSG930 |

GLSG930-VFD |

|

Capacity(t/h) |

≤50 |

|

|

OOC |

<5% |

|

|

Screen Dia.(mm) |

930 |

|

|

Screen Gap(mm) |

0.25-0.5 |

|

|

Lubricating System |

Oil Pressure Full Lubrication |

|

|

Air Pressure |

0.3-0.5Mpa |

|

|

Air Intake(m³/h) |

5 |

|

|

Rotation Speed(Max)(rpm) |

900 |

0~1200 |

|

G-Force |

420 |

450 |

|

Main Motor Power(kW) |

55 |

|

|

Oil Pump Power(kW) |

0.55 |

|

|

Flushing Pump Power(kW) |

4 |

|

|

Separation Efficiency |

<96% |

|

|

Working Temperature(℃) |

≤90 |

|

|

Standard for Explosion-proof |

ExdIIBt4/IECEx/ATEX |

|

|

Weight(kgs) |

4800 |

5000 |

|

Dimension(mm) |

2655x1950x1980 |

2665x1950x1980 |

Treatment Effect:

VFD Decanter Centrifuge:

In the waste treatment system of oil-based mud, Craun adopts a GLLW360-VFD high-speed frequency conversion centrifuge, which has good separation effect on the oil mud with high viscosity, and the separation capacity reaches 3um. The specific gravity of the separated mud is controlled at 1.2g/cm3, which can be directly used in the drilling solid control system, saving the waste treatment cost and realizing the effective utilization of resources.